Reversible propellers have a discing/zero thrust pitch which is different for

every model. Pilots use beta range to adjust their taxi speed. The RPM should

begin from idle and increase up to a certain limit (95% for the PT6 engines).

What I see in MSFS is that initially my RPM decreases and then starts going up

to the limit I set in the prop tables. As an example, for the Kodiak, we have

the following reference values: Low idle RPM: 1080 +/-20 Prohibited

Prop Operation RPM: 450-1050 Max reverse prop RPM: 2090 What I’m

getting in the sim: Low idle RPM: 1080 +/-20 Minimum RPM during beta

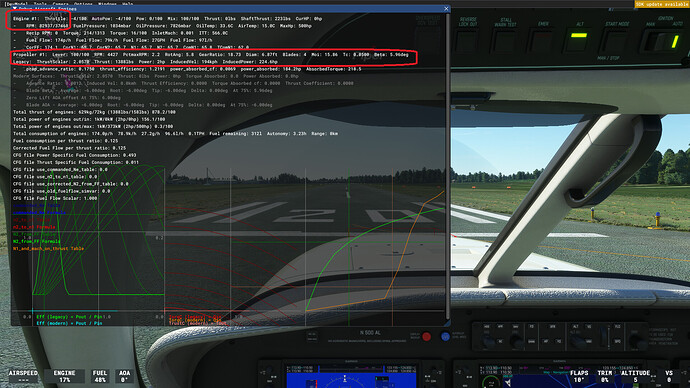

cycle: 790 Max reverse prop RPM: 2090 In the MSFS debug tools I

observed that when the propeller beta is between beta_min and reverse, power

absorbed and efficiency revert to a hardcoded 0.1 which leads to unrealistic

RPM (and thrust). The propeller decreases speed and almost always enters

underspeed mode. I am using legacy tables and even though I can explicitly set

the Cp and n, both are completely ignored and the sim reverts to these default

values. So it would be great if this hardcoded behaviour is removed in one

of the next sim updates, which will allow us to flesh out our propellers and

turboprops fully.

Sylvain, Eric, @FlyingRaccoon @EPellissier I am experiencing the same issue as

Alex… more over because I do not use legacy tables the behaviour is even

worse. The engine and prop thrust continues to spool up forever causing Prop

RPMs above 4000 despite the maximum RPM should be around 1900 on reverse. The

behaviour varies with different blade pitches, for an instance on my engine

between 5.9 to 6.0 triggers the behaviour, spooling the engine RPMs up to

82,000 RPMs when the maximum configured is 37468 RPMs. This causes the RPMS to

go too high (4427) and the thrust totally out of scale.

stop this behaviour, overriding the Prop:RPMs and Engine RPMs have no effect

on the thrust output, so the airplane keeps accelerating pretty much to take-

off speed and the engine debug continues to display the same figures as above.

The problem repeats again at -1 Degrees pitch… but everything works fine

between 2 and 3? which makes no sense. The picture below shows the results

when you move the blade 1.07 degrees out of the 6 degrees zone, is too weird:

I also tried limiting the fuel

to the engine via TURB ENG CORRECTED FF, but it doesn’t work either since the

airplane continues to spool up. What Alex and I are trying to do here is to

simulate the correct behaviour of PT6 engines, where during beta range the

prop blades pitch changes to a very fine pitch slowly until the pilot

continues to push the thrust level to full reverse, at which point full

reverse is engaged. During this stage (Beta Ground operations) the pilot is

basically adjusting the pitch blades manually to adjust the taxi speed. The

engine stops using the governor and instead uses fuel flow to control the

propeller RPMs so they don’t go over the max RPM or under RPMs. Ideally, we

also need the ability to control fuel flow properly to code the behaviour

correctly. If we could have something like we have with forced prop beta, to

implement forced fuel flow, perhaps we could prevent the engine from going

nuts like this?. I am leaving here attached the description of these

operations from the PT6 engines. fdocuments.net_pt6a-engine-

explanation.pdf We would really

appreciate your help with this subject, both me an Alex have several new

projects using PT6 engines which are affected by these behaviours, and we

would like to find the best way to be able to move such projects forward.

Thanks in advance for taking the time to look into this. Best Regards, Raul

Morales CEO Flight Sim Technologies www.FSReborn.com

Looking at Raul’s post, at 5.89 degrees of pitch his Cp (power_absorbed) is

very small, which causes the RPM to go crazy high. With beta less than 5

degrees (other photo) his Cp and efficiency are both 0.1 which is the

hardcoded behaviour I also noticed. Given that I’m using legacy and he’s using

modern, there is one common problem in both cases: the propeller has hardcoded

Cp and n for certain ranges, which seem to be between -3 and +5 degrees of

pitch. The other problem has to do with the “modern” modern propeller (not the

one from v1.0) which completely miscalculates the performance when it comes to

Turboprops. Additionally, the two modern propeller models seem to have weird

behaviours for reverse pitch, leading to propeller overspeed when you go into

full reverse. Without getting too technical, the PT6 engine in particular has

two behaviours worth observing, per the maintenance manual:

- Initially, the propeller RPM increases because it goes into finer pitch (lower Cp) and of course, N2 increases. The fuel control unit adjust the fuel flow to keep the Ng at idle during that time.

- As you pull the power lever further back, the propeller pitch starts going below ground fine and towards reverse the more you pull it. Np increases up to 95% of the max governed value. At the same time Ng begins to increase, but the FCU controls Ng so that Np will not increase past 95% Np

What is happening in MSFS is odd:

- Using legacy tables, one can limit the propeller to 95% Np. Ng will be dragged along by the propeller, so retaining idle Ng during the initial beta stage is impossible without some custom coding. Ng will be limited by propeller speed. When beta reaches -3 to +5 degrees, hardcoded behaviours cause the propeller to underspeed and not produce correct thrust, ignoring the tables completely.

- Using the modern flight model and no forced beta, any throttle setting below 0% will immediately take the propeller to full reverse pitch. Ng is then used to scale the thrust produced by the propeller. The issue is that the propeller will overspeed well before maximum Ng is achieved.

- Using the modern flight model and forced beta will yield both problems at once. You will experience propeller underspeed between -3/+5 degrees and overspeed when you go into full reverse.