Hello Team Asobo and FlyingRaccoon, I have one more question. Hopefully this

will be the last on Turboprops. How exactly does one adjust Prop RPM top end?

Lets say mine is spiking to a max of 4K RPM. I need it to be at 1200 to 1400

RPM max, (very low). Gear Reduction does very very little. Is this done with

the prop_power_cf table? Many thanks, Bill, (otgebp) Lionheart Creations

Hello @lyonhaart001 What do you mean by “Gear

Reduction does very very little”? Prop rpm should be in direct relation of

your N2 RPM ( N2 rpm / gear_reduction_ratio ) Regards, Sylvain

Good morning Sylvain, By setting gear Reduction to 400.1, I was still at 2500

RPM, where before it was 4K+. My thoughts are, perhaps I was on the wrong

path, but maybe that is the route. Should I just keep increasing gear

reduction? If that is the route to go, I am very happy with that. The gearbox

on the real-world engine is quite big. Bill LHC

I tried bumping Gear Reduction to 880.1, then to 2020.1 and Prop RPM was still

at roughly 3400 RPM at highest spike. It did lower a bit on idle, but not on

spike, Max Throttle.

shows idle, 50% condition lever. With Gear Reduction at 2020.1, I can get an

idle of 660 prop RPM, but she still spikes up to 3400K RPM on the prop. This

is my present ‘engines’ config. I am using an early Asobo turboprop model. The

new one for KingAir and Caravan couldnt be used as I couldnt increase the

power enough. The old versions are easily tuneable. Bill LHC

engines.zip

Did you monitor the N2 RPM as well and if so, what’s its value? For example,

here’s the TBM 930 at full throttle: Prop rpm is engine rpm / gear ratio

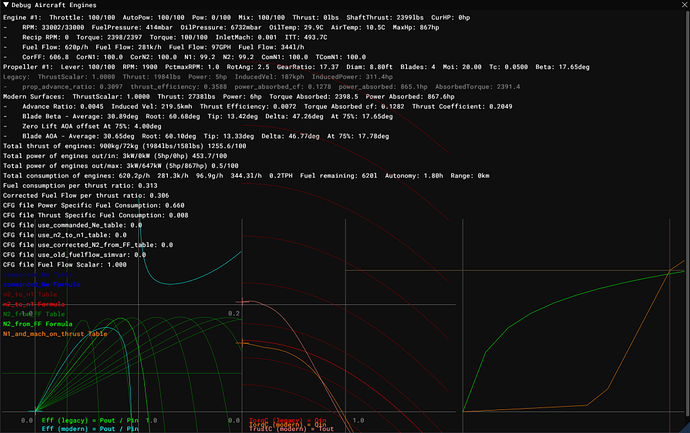

Many thanks Sylvain. Interesting. My N1 RPM was off the charts at full

throttle. Thank you for pointing out these functions in the engine debug

window. I am very grateful. This also shows my ‘spike issue’ better, bronze

colored arc, bottom right. The TBM has this also, but mine for some reason

kicks in at 55% approximately and jumps high. Perhaps a full redo of this

section and start over. ![]() Thanks again. I hope SU9 is going smoothly. Bill

Thanks again. I hope SU9 is going smoothly. Bill

LHC

Man, this is a nightmare. ![]() It used to be that adjusting power scalers for

It used to be that adjusting power scalers for

either turboprop or propeller increased that section’s output. But not

anymore. Scalers arent working. If I increase the thrust of the prop, nothing.

If I increase the SHP power to the amount that gets the plane to the right

speed, my prop is doing 5,000 RPM instead of 2000, and i need that at 1200

average / 1400 spiked, and also my turbine is into the one million zone,

somehow. I have to adjust SHP to nearly 12K SHP to get 390 knots max. Gear

ratio at that level does nothing. Gear Ratio at 20000.1 does nothing when your

turbine is cooking at 1M+. I tried an older version Asobo Caravan ‘engines’

file, adjusted it to run at 1200 RPM prop revolutions, kept SHP down and went

for thrust scaler on propeller to just get around it that way, and nothing

happened. Scalers do not function anymore. If only there was an easy way to

get my plane to do 390 knots max, prop at 1200 / 1400 RPM.

Propeller thrust scalar do function. Here’s a comparison of Caravan

performance with thrust_scalar = 1.0 vs thrust_scalar = 2.0

You must proceed in order. 1 -

Configure the turbine according to the POH (proper N1, N2, output hp/thrust) 2

- Configure the propeller the same way (size, beta, thrust, etc…) 3 - Adjust

aircraft performances. You don’t want to do 3 by completely changing 1 and 2

if they were correct or you’ll have other problems. If your aircraft

performance is not matching your expectations, first make sure you’re getting

correct thrust from 1 and 2. Then, check your aircraft weight, lift and drag

as this will also impact performance. Regards, Sylvain

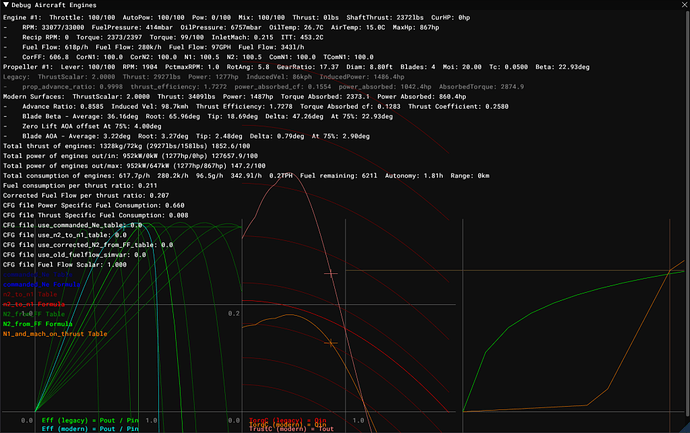

Hey Sylvain, I tried your version new version, Caravan SU9, latest Engine

config. I changed SHP from 867 to 2867, rebuilt, and it did 200 knots. I then

tried 4867 SHP, and that too flew 200 knots. I then made it 12867 SHP and it

too flew 200 knots. I verified through Aircraft Editor that it was loading the

data after each build. I then tried the Scaler, advancing it to 6.0 to see if

I got a result, and no. 200 knots.

I just cant seem to get the

speeds I need.

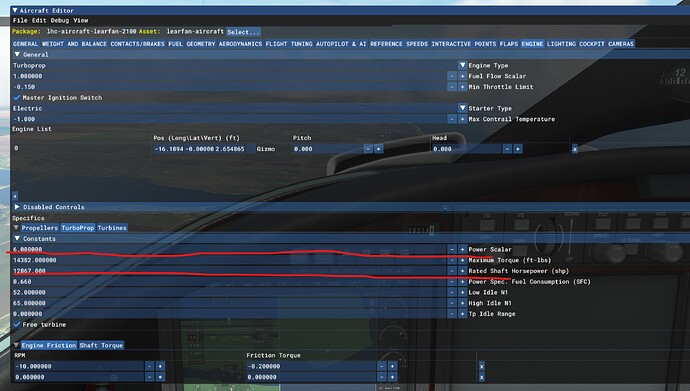

This is my Turboprop section; [TURBOPROP_ENGINE] tp_high_idle_throttle_pos=0

power_scalar = 6 ; Scalar on Turboprop power maximum_torque = 2397 ; Maximum

torque available (ft-lbs) torque_automatic_limit=2500 engine_friction_table =

-10:-0.2, 0:0, 10:0.5, 70:0.5, 105:0.5 ; Rpm → Friction torque

n1_to_shaft_torque_table = 0:0, 66:0.05, 100:1.0, 110:1.1 ; Corrected N1 →

Shaft Torque rated_shaft_hp = 12867 PowerSpecificFuelConsumption = 0.66 ; SFC

tp_idle_range = 0.00 ; increase of n1 idle at high mixture (Percent)

free_turbine = 1

With last years version of Caravan engine config (I saved it) I can change SHP

to 12K SHP and I get my 390 knots at max throttle, flat out. But for some

reason, the newest Caravan system doesnt want to fly faster.

I think I am going to stick with my present original Asobo version with the

prop doing over 4K. At least the speeds are working. Perhaps someday I can

find a way to reduce the prop RPM and keep other speeds proper. Thanks anyways

for your help. I hope everything is going well at Asobo. Kind regards, Bill

Bill, You also need to adjust your aircraft aero configuration. Just putting

more thrust through it doesn’t guarantee a particular speed. The current

system is much more grounded in reality, so if you need more speed and you

have the right thrust, then you need to decrease drag. That being said, I’m

curious as to what you are trying to model that would be capable of nearly

400kts on a single PT6. That puts the plane well above even superfast turbine

singles like the TBM and the M50. That would be an extremely small and light

plane for a turbine like that or something far more slippery than has been

demonstrated yet in the real world. And, you’re missing a critical piece of

Sylvain’s advice: you must also configure the prop accordingly. The engine may

be capable of putting out that much horsepower, but it isn’t going to matter

for much if the prop is drag limited anyhow and won’t go any faster or more

efficiently. That’s the reason the old file is working more when you just

crank up the scalar, because the new file also includes the correct prop

settings: shape, thrust, Cd/Cl, twist, etc Again, none of these things should

be adjusted in isolation.

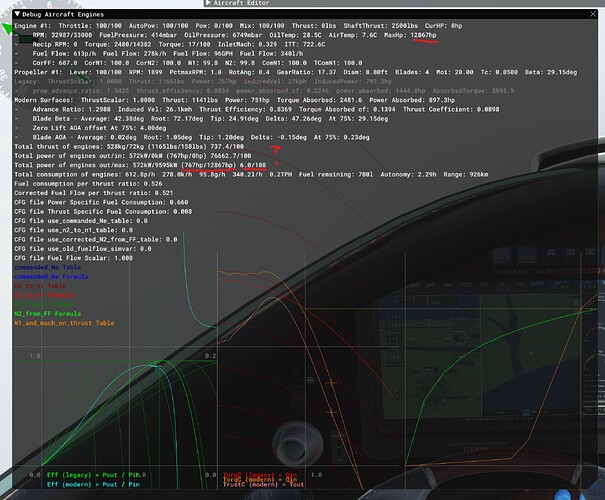

Thanks Matt for your input. The engine I am modelling is the PW127XT, the

100/150 series, slow RPM with about 2600 SHP approximate. The TBM is running

about 650SHP approximate. It ended up that I couldnt even get a power output

‘boost.’ It was showing output 750, and max output 12K, when experimenting

trying to get it to boost up. Something in the formula to get it to rise the

power output is being missed. Scaler (last result), Max SHP, etc, did nothing.

It ‘must’ be there somewhere. I just couldnt find it. Something was locking it

down to 750 SHP output max. A governor or something setting that I missed or

cannot see. Bill

@lyonhaart001 Not sure if this was finalized

but I have found the following works just great take the MAX RATED ENGINE RPM

for example 38100 (for My PT6-45) divide this by your Published MAX PRPM (in

my case 1870) therefore - 38100 / 1870 = 20.374 set Gear_reduction to =20.374

Bingo Bango ![]()