Version: 1.4.16.0

Frequency: Consistently

Severity: Low

Bug description:

In a fuel system with a line connecting two junctions, with the expectation that fuel can flow either way in that line, depending on which engine is on, what valves are open, etc. The line pressure values don’t make any sense in some occations.

Repro steps:

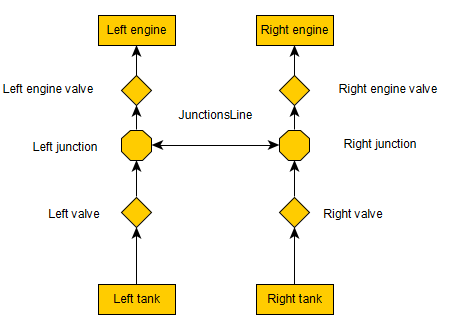

Have a plane with the below fuel system configuration.

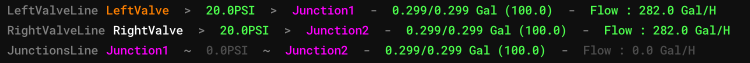

Open the Fuel system debug tool and make sure both tanks have fuel and all valves are open. See that the JunctionsLine connecting the two junctions has 0 PSI pressure, even with both the ValveLine lines (and actually every other line) going into the junctions having 20 PSI. I’m not a fluids engineer, but my acquaintance mr. Copilot Chat said this should be impossible. The flow being 0 I believe is to be expected.

What might be worse is that there’s a directionality to the lines in regards to which way you define them in the flight_model.cfg. The JunctionsLine here is defined going from Junction1 to Junction2 so “left to right”. If I now close the RightValve, so fuel is only coming from the left tank and going “left to right” in the JunctionsLine, the JunctionsLine jumps to 20 PSI, but if I close the LeftValve, it goes to -20 PSI. And if I switch the JunctionsLine to go “right to left”, ie. comment and uncomment Line.7 from the config, the pressure values are reversed when closing the valves.

The good thing in this is that the flow doesn’t suffer from this directionality. If atleast one engine is running, the flow will go positive when closing either tank valve.

Ultimately, this is hampering me building my EICAS fuel page. I want the pilot to be able to see what is happening with the fuel, what level the tanks are, where it’s flowing, what position valves are, etc. If I use the pressure values of lines, I can workaround the negative values with doing a “Math.abs() > 10” to pick an appropriate colour to colour the lines. But this doesn’t work when the pressure is 0. Maybe I’ll have to use the flow values, but they do seem to fluctuate a lot.

[FUEL_SYSTEM]

Version = Latest

Engine.1 = Name:LeftEngine#Index:1

Engine.2 = Name:RightEngine#Index:2

Tank.1 = Name:LeftTank#Capacity:1532#UnusableCapacity:0#OutputOnlyLines:LeftOuterPump1In#Priority:3

Tank.2 = Name:RightTank#Capacity:1532#UnusableCapacity:0#OutputOnlyLines:LeftInnerPump1In#Priority:3

Line.1 = Name:LeftPumpIn#Source:LeftTank#Destination:LeftPump

Line.2 = Name:RightPumpIn#Source:RightTank#Destination:RightPump

Line.3 = Name:LeftPumpOut#Source:LeftPump#Destination:LeftValve

Line.4 = Name:RightPumpOut#Source:RightPump#Destination:RightValve

Line.5 = Name:LeftValveLine#Source:LeftValve#Destination:Junction1

Line.6 = Name:RightValveLine#Source:RightValve#Destination:Junction2

Line.7 = Name:JunctionsLine#Source:Junction1#Destination:Junction2

;Line.7 = Name:JunctionsLine#Source:Junction2#Destination:Junction1

Line.8 = Name:Engine1ValveLine#Source:Junction1#Destination:LeftEngineValve

Line.9 = Name:Engine2ValveLine#Source:Junction2#Destination:RightEngineValve

Line.10 = Name:Engine1Line#Source:LeftEngineValve#Destination:LeftEngine

Line.11 = Name:Engine2Line#Source:RightEngineValve#Destination:RightEngine

Junction.1 = Name:Junction1#InputOnlyLines:LeftValveLine

Junction.2 = Name:Junction2#InputOnlyLines:RightValveLine

Valve.1 = Name:LeftValve

Valve.2 = Name:RightValve

Valve.3 = Name:LeftEngineValve

Valve.4 = Name:RightEngineValve

Pump.1 = Name:LeftPump#Pressure:20#TankFuelRequired:LeftTank#DestinationLine:LeftPumpOut#Type:Electric#Index:1

Pump.2 = Name:RightPump#Pressure:20#TankFuelRequired:RightTank#DestinationLine:RightPumpOut#Type:Electric#Index:2

fuel_type = 2

Attachments: